-

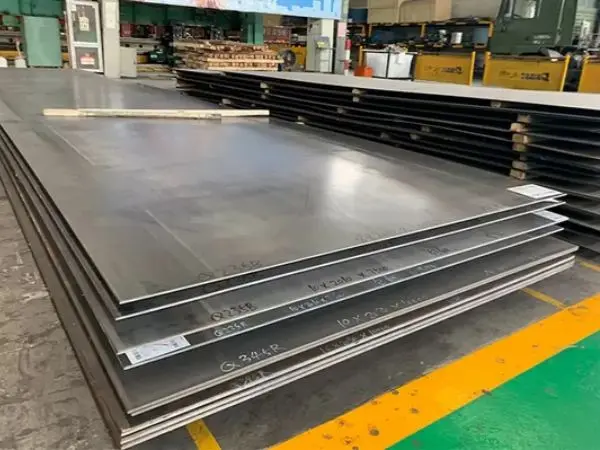

Density of carbon steel plate and influencing factors

The density of carbon steel plates typically hovers around 7.85g/cm³, though it can fluctuate due to various factors such as carbon content, heat treatment, and manufacturing processes. While this value serves as a general reference, the actual density can vary slightly based on specific conditions.

2025-02-18

-

Service life of stainless steel plates

Stainless steel plates, known for their high performance and durability, are widely used across various industrial sectors and in everyday applications. A common question that arises is, "How long can stainless steel plates last?" The answer to this depends on several factors.

2025-02-18

-

Standard specifications and usage precautions of water pipe elbows

Water pipe elbows are essential components used in plumbing systems to connect pipes at various angles. They help redirect the flow of water or other fluids in different directions. To ensure their efficient operation and long lifespan, it’s crucial to adhere to standard specifications and usage precautions. Below is a guide to the standard specifications and usage precautions for water pipe elbows.

2025-02-17

-

How to avoid rusting of carbon steel pipes?

Carbon steel is an alloy steel with a high carbon content. While it offers strength and durability, it is prone to rusting due to its iron content. When exposed to oxygen and moisture in the environment, carbon steel undergoes oxidation, forming iron oxide (rust). The corrosion resistance of carbon steel pipes (CS pipes) is relatively low, especially in damp, acidic, or alkaline conditions. Here’s an overview of the causes of rusting in carbon steel pipes and how to prevent it.

2025-02-17

-

Introduction to the types of finned tubes

Finned tubes are crucial components in heat exchangers, designed to enhance heat transfer efficiency by increasing the surface area of the tube. By adding fins to the surface, either externally or internally, the overall heat transfer rate is significantly improved. These tubes come in various types, which are classified based on factors such as manufacturing process, fin shape, materials, and application. Here's a breakdown of the main types of finned tubes.

2025-02-14

-

What are the uses of finned tubes?

Finned tubes are highly effective heat exchange components used in various industrial and commercial applications due to their ability to increase the surface area available for heat transfer. By attaching fins to the tube's surface, these tubes significantly improve thermal efficiency, making them ideal for applications where heat needs to be efficiently transferred or dissipated. Below are some of the common uses of finned tubes.

2025-02-14

-

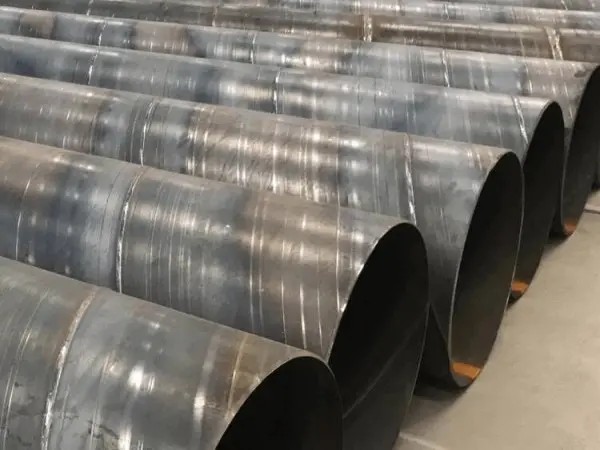

ASTM A500 SSAW steel pipe sizes

ASTM A500 typically refers to cold-formed welded carbon steel pipe used for structural applications. However, SSAW (Spiral Submerged Arc Welded) pipes, which are made using a different manufacturing process, are typically not categorized under ASTM A500. Instead, SSAW pipes are usually covered by specifications like ASTM A53 or ASTM A252, depending on their application. That said, if you're looking for the general size range of SSAW steel pipes, here are the typical dimensions.

2025-02-13

-

ASTM A500 Grade B ERW carbon steel pipe

ASTM A500 Grade B is a specification for cold-formed welded and seamless carbon steel structural tubing. It is widely used for structural applications such as building frames, bridges, and various other construction projects. The "Grade B" designation refers to a specific material grade that is required to meet certain mechanical properties. For ASTM A500 Grade B ERW (Electric Resistance Welded) carbon steel pipe, here are some of the key characteristics.

2025-02-13

-

ASTM A252 SSAW steel pipe sizes

ASTM A252 is a standard specification for welded and seamless steel pipes used for piling applications, commonly known as SSAW (Spiral Submerged Arc Welded) pipes. The sizes for ASTM A252 SSAW steel pipes typically follow a range of standard dimensions, with varying wall thicknesses and outer diameters to suit different piling applications. Here’s an overview of the common sizes of ASTM A252 SSAW steel pipe.

2025-02-12

-

ASTM A252 GR.3 SSAW steel pipe

ASTM A252 Gr.3 is a specification for welded and seamless steel pipes used for piling applications, primarily designed for structural and foundation purposes. When applied to SSAW (Spiral Submerged Arc Welded) steel pipes, this standard defines the requirements for pipes that are used in large-scale construction and infrastructure projects, such as foundations, bridges, and other load-bearing structures.

2025-02-12

-

Benefits of ASTM A53 SSAW steel pipe

SSAW (Spiral Submerged Arc Welded) steel pipes, particularly those manufactured according to ASTM A53 standards, offer a variety of benefits that make them an excellent choice for a wide range of industrial applications. Known for their strength, versatility, and cost-effectiveness, ASTM A53 SSAW steel pipes are a popular option in the construction, oil and gas, water supply, and other sectors where reliable piping solutions are essential. Below are some of the key advantages of using ASTM A53 SSAW steel pipes.

2025-02-10

-

ASTM A53 SSAW steel pipe

ASTM A53 is a standard specification set by the American Society for Testing and Materials (ASTM) that covers seamless and welded black and galvanized steel pipes intended for various applications. When applied to SSAW (Spiral Submerged Arc Welded) steel pipes, ASTM A53 ensures that these pipes meet specific quality and performance standards suitable for structural and industrial uses.

2025-02-10