-

Common applications of ERW pipes

Electric Resistance Welded (ERW) pipes are widely used across various industries due to their strength, durability, and cost-effectiveness. These pipes are manufactured with precision and uniformity, making them suitable for applications ranging from oil and gas transportation to construction and automotive manufacturing. Below are some of the key application areas of ERW pipes.

2025-03-14

-

An introduction to 426 SSAW steel pipe

426 SSAW steel pipe is an important pipeline material, widely used in construction, oil, natural gas, and other fields. With its unique SSAW structure and excellent performance, it plays a crucial role in modern engineering. Here's an overview of the 426 SSAW steel pipe.

2025-03-14

-

Production and manufacturing methods of seamless carbon steel pipe

Seamless carbon steel pipes are produced using various methods, including hot-rolling, cold-rolling, cold-drawing, and extrusion. The primary difference between cold-drawn and hot-rolled seamless steel pipes is their precision. Cold-drawn pipes typically offer higher precision compared to hot-rolled pipes, with cold-drawn pipes generally having an accuracy of around 20 wires, while hot-rolled pipes have an accuracy of around 100 wires. As a result, cold-drawn seamless steel pipes are preferred for mechanical processing and parts manufacturing due to their superior precision.

2025-03-13

-

Specification size table of cold drawn seamless carbon steel pipe

Based on the GB/T 3639-2018 standard (Cold Drawn or Cold Rolled Precision Seamless Steel Pipe), the following is the commonly used specification size table for cold drawn seamless carbon steel pipes.

2025-03-13

-

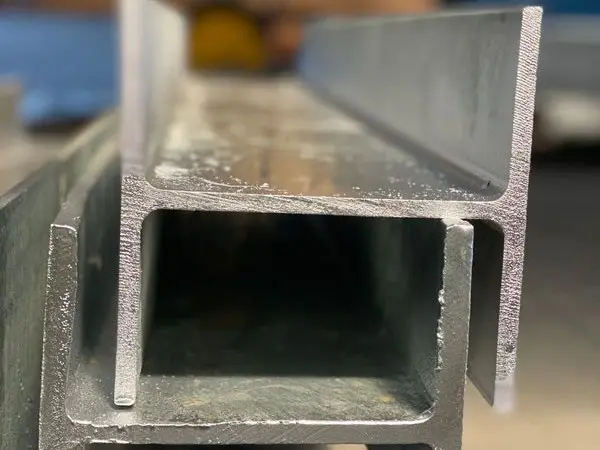

How are steel I beams are made?

Steel I-beams are essential components in construction and structural engineering, known for their strength and efficiency in load-bearing applications. The manufacturing process of I-beams involves different techniques, each tailored to specific structural requirements. Generally, steel I-beams are produced through four primary methods: rolling, extrusion, welding, and riveting.

2025-03-12

-

Key properties of steel I beams

Steel I-beams are widely used in construction and structural applications due to their exceptional strength and efficiency in supporting loads. When designing with steel I-beams, it is crucial to consider several key properties that determine their performance and suitability for different projects.

2025-03-12

-

Structural steel I beam grades

Structural steel I-beams come in various grades, each designed to meet specific load-bearing and performance requirements. The selection of the appropriate grade depends on factors such as strength, weldability, and resistance to environmental conditions. This article will briefly introduce structural steel I beam grades.

2025-03-11

-

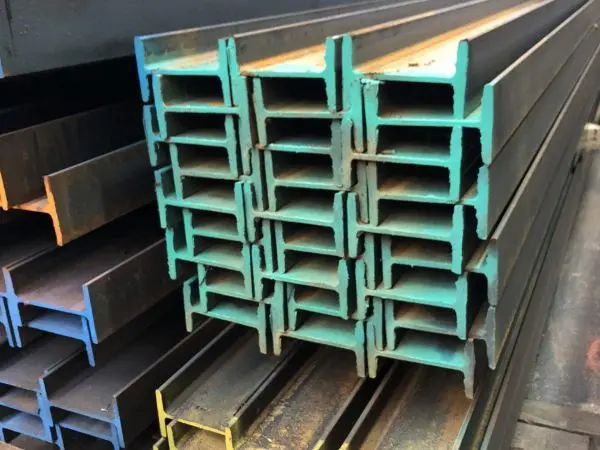

What are structural steel steel I beams used for?

Structural steel I-beams are widely used in steel construction due to their exceptional strength, efficiency, and load-bearing capabilities. These beams play a crucial role in the primary framework of steel-framed buildings, ensuring structural integrity by effectively transferring loads from the rooftop down to the foundation. Their design allows them to handle heavy loads while maintaining cost-effectiveness, making them a popular choice across various industries.

2025-03-11

-

Importance and methods of recycling waste pipe flanges

The recycling of waste pipe flanges plays a vital role in environmental protection and resource conservation. As essential components in petroleum, chemical, and power industries, flanges are widely used for pipe connections. However, due to wear, aging, or technological upgrades, many flanges become obsolete and, if not properly handled, can contribute to environmental pollution. Efficient recycling of these materials is crucial for sustainable development. This article will briefly introduce importance and methods of recycling waste pipe flanges.

2025-03-10

-

How to detect defects in carbon steel welded pipes?

Detecting defects in carbon steel welded pipes is crucial for ensuring their structural integrity, safety, and performance. Several non-destructive testing (NDT) methods are commonly used to identify welding flaws, cracks, thickness variations, porosity, and other irregularities. This article will briefly introduce how to detect defects in carbon steel welded pipes.

2025-03-10

-

The electrical characteristics of high-frequency welded pipes

Steel pipes serve as fundamental materials in various industries, including construction, transportation, and energy. Among them, high-frequency welded pipes (ERW pipes) have gained widespread use due to their efficient production process and superior performance. This article delves into the electrical characteristics of high-frequency welded pipes and their influence on product functionality.

2025-03-07

-

Annealing process of stainless steel plates

In the field of metal material processing, stainless steel plates are widely used across industries such as construction, automotive manufacturing, and food processing due to their outstanding corrosion resistance, high strength, and excellent processability. Among the various treatment methods, the annealing process plays a crucial role in enhancing the material’s properties. But what exactly is the annealing process for stainless steel plates, and why is it so important?

2025-03-07