-

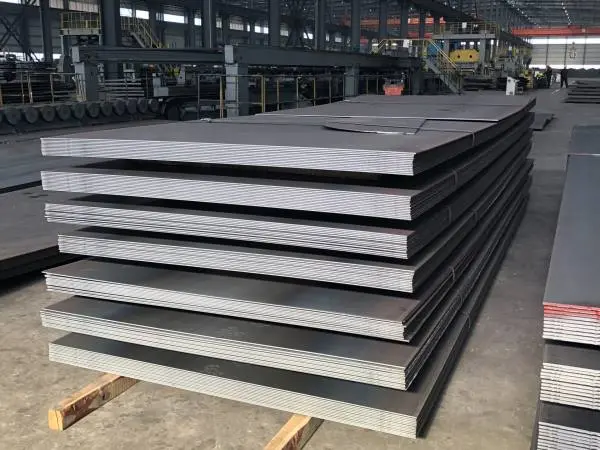

Advantages and disadvantages of carbon steel plates

Carbon steel plates are widely used in various industries due to their balance of strength, affordability, and versatility. However, like all materials, they come with both advantages and limitations that influence their application. Here’s a closer look at the benefits and drawbacks of carbon steel plates.

2025-02-26

-

Manufacturing process of carbon steel plates

Carbon steel plates are essential materials in industrial applications, known for their wide use and strong performance. This article will briefly introduce manufacturing process of carbon steel plates.

2025-02-26

-

Flattening test for ERW pipe

The flattening test for ERW (Electric Resistance Welded) pipes is a standard procedure used to evaluate the mechanical properties and quality of the welded joints in ERW pipes. The test involves applying a compressive force to the pipe until it is deformed in order to assess its ability to withstand stress without failure, particularly at the welded area. This test is essential for ensuring the structural integrity of the pipe, especially in applications where the pipe may be subjected to bending or compressive loads.

2025-02-25

-

FBE coating process of FBE coated pipe

The FBE (Fusion Bonded Epoxy) coating process is a widely used method for providing a protective coating to steel pipes, especially in applications such as pipelines for oil, gas, and water transport. The primary purpose of the FBE coating is to prevent corrosion and extend the service life of the pipes, especially in harsh environmental conditions. The FBE coating is known for its strong adhesion, excellent corrosion resistance, and long-term durability. Here's an overview of the typical FBE coating process of FBE coated pipe.

2025-02-25

-

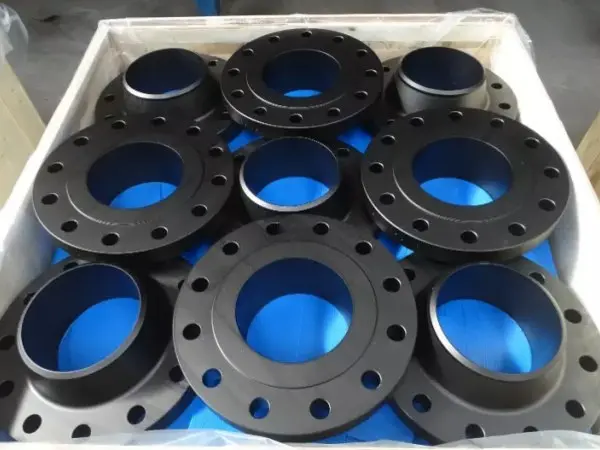

US standard pressure grade of carbon steel pipe flanges

American Standard carbon steel pipe flanges are classified into various pressure grades according to the ANSI/ASME B16.5 standard. These classifications are based on the flange's capacity to withstand the working pressure in a pipeline system, with additional considerations for factors such as temperature impacts on performance. The purpose of these pressure grades is to ensure the safety and reliability of flanges under different working conditions, allowing for seamless integration with pipeline systems requiring various pressure levels. Below are the specific pressure grades and their respective ranges.

2025-02-24

-

A complete guide to single flange steel pipe

Steel pipes are essential in modern construction, engineering, and manufacturing, with single-flange steel pipes standing out due to their unique features and broad application. As a common building material, steel pipes are widely used in structural frameworks, pipelines, and machinery production. The single-flange steel pipe, a specialized form of this material, offers distinct advantages and a wide range of uses. Here's a complete guide to single flange steel pipe.

2025-02-24

-

Selection guide of pipe flange

Selecting the right pipe flange is essential for ensuring the smooth and efficient operation of a pipeline system. Factors such as pipe material, size, and pressure must be carefully considered. Furthermore, attention to detail during installation and regular maintenance is crucial to prolong the service life of the flange and ensure reliable pipeline performance.

2025-02-21

-

Industrial cleaning methods for stainless steel plates

There are four common industrial cleaning methods used for stainless steel plates: physical cleaning, electronic cleaning, electrostatic cleaning, and chemical cleaning. Continental Steel Co., Ltd. provides an overview of the principles and treatment methods for each of these approaches.

2025-02-21

-

How to improve the hardness and strength of seamless steel pipes?

The hardness and strength of seamless steel pipes (SMLS) are primarily influenced by the type of steel used and the heat treatment methods applied. Below are several techniques to enhance the hardness and strength of seamless steel pipes.

2025-02-20

-

Purpose and method of bending SMLS steel pipes

In real-world applications, the straight form of seamless steel pipes (SMLS) is not always suitable. Due to their standard long lengths, they may not meet the specific needs of certain scenarios. Therefore, bending is an essential process to adapt the pipes to various requirements. Continental Steel Co., Ltd. has summarized the key information regarding the bending of seamless steel pipes.

2025-02-20

-

Seamless carbon steel pipes cutting technology

Seamless carbon steel pipes are a crucial foundational material across various industries, playing an indispensable role due to their unique properties. As a core material in industrial production, seamless carbon steel pipes are integral to many manufacturing processes, including their cutting. With advancements in science and technology, the cutting techniques for seamless carbon steel pipes have evolved, leading to improved precision and efficiency. This article will delve into various cutting methods and highlight their importance in modern industrial applications.

2025-02-19

-

Introduction to stainless steel plate from Continental Steel

Stainless steel plates are known for their sleek, bright surface, exceptional plasticity, toughness, and mechanical strength, making them highly resistant to corrosion from acids, alkaline gases, solutions, and various other media. Available in different thicknesses, such as 3mm, 16 gauge, and 2mm, these sheets offer versatility in various applications. Here's an overview of the stainless steel plate from Continental Steel.

2025-02-19