- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

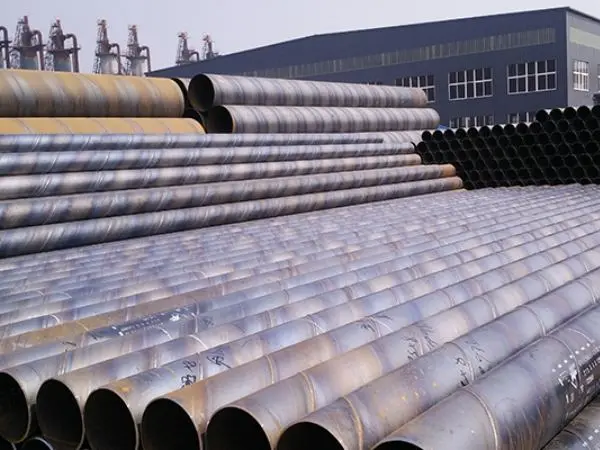

As a crucial engineering material, SSAW steel pipes find extensive applications across various fields. SSAW steel pipes come in different specifications, each with distinct characteristics and performance attributes that suit specific uses. Here’s an overview of the types, uses, and performance comparisons of SSAW steel pipes to help in selecting the appropriate spiral pipes for different needs.

1. Types and Characteristics of SSAW Steel Pipes

SSAW steel pipes can be categorized based on material, production process, specifications, and sizes. The most common types include:

Carbon Steel Spiral Pipe: Known for its cost-effectiveness and corrosion resistance, commonly used in construction, chemical industries, and petroleum.

Stainless Steel Pipe: Offers excellent corrosion resistance and is aesthetically pleasing, suitable for transporting corrosive media like acids and alkalis.

Alloy Steel Pipe: High-strength and corrosion-resistant, ideal for high-pressure, high-temperature, and high-strength applications such as chemical plants, petroleum, and nuclear power.

Galvanized Spiral Pipe: Specially treated for enhanced corrosion resistance, used for transporting gas, liquids, and other media in environments requiring extra protection.

Each type varies in size, wall thickness, and weight, leading to different characteristics and suitable application areas.

2. Use Cases of SSAW Steel Pipes Based on Material

Carbon Steel SSAW Pipe: Primarily used for transporting water, gas, and other liquids. It's widely utilized in construction, chemical industries, and petroleum due to its good corrosion resistance, long service life, and affordability.

Stainless Steel SSAW Pipe: Best for conveying corrosive media like acids, alkalis, and salts. Its advantages include superior corrosion resistance and an appealing appearance, making it suitable for various environments.

Alloy Steel SSAW Pipe: Ideal for high-pressure and high-temperature conditions, such as in the chemical industry, petroleum, and nuclear power, due to its strength and corrosion resistance.

Galvanized SSAW Pipe: Commonly used for gas and liquid transport, especially in scenarios demanding high corrosion resistance. It boasts excellent anti-corrosion properties and a long service life.

3. Performance Comparison of SSAW Steel Pipes

Comprehensive Performance: The overall performance varies with different specifications. Generally, larger-diameter, thick-walled pipes offer higher strength and pressure resistance, while smaller-diameter, thin-walled pipes excel in toughness and impact resistance.

Service Life: The lifespan of an SSAW pipe is influenced by factors such as material, production process, and the nature of the medium being transported. Stainless steel pipes typically last longer, whereas carbon steel pipes have a comparatively shorter lifespan.

Process Performance: The ease of processing differs among specifications. Large-diameter pipes are more challenging to bend and cut, while small-diameter pipes are easier to process and install.

4. Choosing the Right SSAW Steel Pipe Specifications

When selecting SSAW steel pipe specifications, consider the following:

Application Scenario: Choose the appropriate type and specification based on the actual use case. For example, stainless steel or galvanized pipes are ideal for transporting corrosive media, while alloy steel pipes are better suited for high-pressure, high-temperature applications.

Medium Properties: Understand the medium's properties, including temperature, pressure, and corrosiveness, to select the right material and specification.

Process Performance: Consider processing and installation requirements to select suitable specifications and types.

Economy: Balance the cost-effectiveness with the required performance and durability to choose the most economical option.

In summary, SSAW steel pipes vary in characteristics and application ranges based on their specifications and materials. To make an informed selection, it's important to consider the specific application scenario, medium properties, process requirements, and economic factors. Additionally, proper maintenance is crucial to ensure the longevity and safety of the pipes in use.