- Phone0086 731 8564 8255

- E-mailsales@cscsteel-manufacturing.com

-

When selecting materials for piping systems, it is essential to understand the differences between various types of pipes, particularly galvanized steel pipes and plastic-coated steel pipes. Both have unique properties and advantages, making them suitable for different applications. Below are the key differences between these two types of pipes.

Manufacturing Process

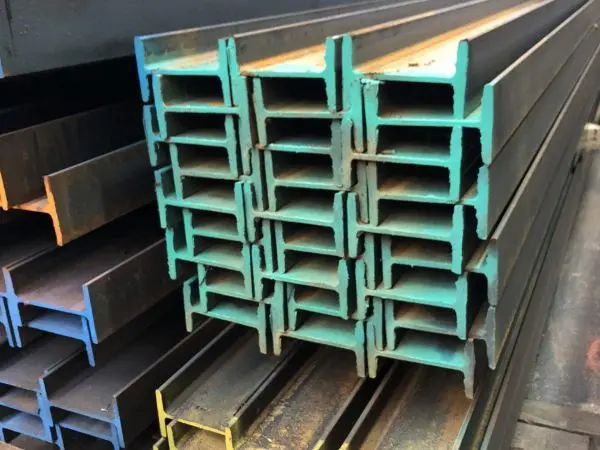

- Galvanized Steel Pipes:

These pipes are produced by creating an alloy layer through the reaction of molten metal with an iron matrix, effectively bonding the coating to the pipe. The process involves pickling the steel pipe to remove iron oxide from its surface, followed by cleaning in a solution of ammonium chloride or zinc chloride (or a combination of both). The pipe is then immersed in a hot-dip plating tank. The main advantages of galvanized pipes are the uniform coating, strong adhesion, and extended service life. However, the quality of these pipes has declined in recent years as many manufacturers reduce the thickness of the galvanized layer for cost-saving purposes. Originally, galvanized pipes were expected to last 7-8 years, but now their lifespan is often only 2-3 years.

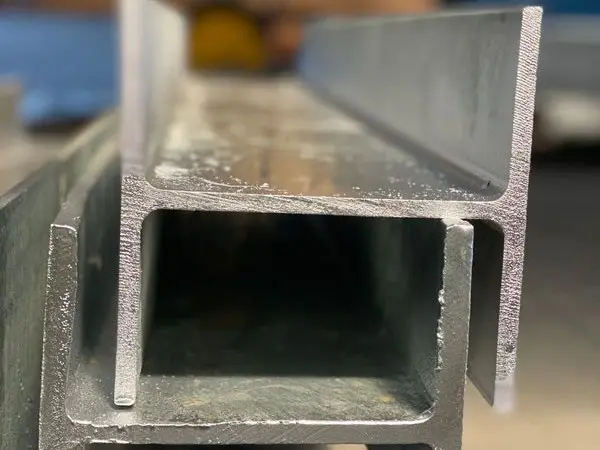

- Plastic-Coated Steel Pipes:

Plastic-coated steel pipes combine the strength of steel with the protective properties of plastic, offering a versatile solution for pipes of various calibers. Unlike galvanized pipes, plastic-coated pipes offer multiple connection methods, including threaded, grooved, welded, flange, and bimetallic welding connections. These pipes address the shortcomings of galvanized pipes by providing corrosion resistance for both the inner and outer layers, making the internal and external surfaces smooth without reducing the flow diameter. This improvement increases transportation efficiency. Plastic-coated steel pipes are known for their strong adhesion, excellent impact resistance, and long service life, which can be more than five times longer than that of galvanized pipes. Additionally, they can perform well in harsh environmental conditions, ensuring reliable operation over time.

Summary:

Galvanized Steel Pipes: Good adhesion, uniform coating, but shorter lifespan due to thinner zinc layers.

Plastic-Coated Steel Pipes: Higher corrosion resistance, multiple connection options, smooth internal and external surfaces, significantly longer service life, and better performance in harsh environments.