-

Three ways to produce precision welded steel pipes

This article will briefly introduce three ways to produce precision welded steel pipes.

2024-06-13

-

Corrosion insulation performance of spiral steel pipe

Anti-corrosion insulation pipes, known for their corrosion resistance and excellent insulation properties, have become increasingly popular in building construction. Their usage and development continue to evolve, enhancing their applications across various industries.

2024-06-12

-

3 different types of spiral weld seam?

SSAW (Spiral Submerged Arc Welded) carbon steel pipes are extensively utilized in various construction projects due to their strength, durability, and versatility.

2024-06-12

-

Carbon steel pipe hardness

The hardness of carbon steel pipes is commonly measured using three indicators: Brinell, Rockwell, and Vickers hardness tests.

2024-06-12

-

How to paint carbon steel pipes?

Carbon steel pipes are made from an iron-carbon alloy that retains high tensile strength and can be shaped during manufacturing. These pipes, like black steel pipes, are commonly used due to their strength and versatility. However, it's crucial to protect their surfaces from corrosion, as their ferrite composition makes them prone to rust when exposed to water.

2024-06-12

-

Corrosion properties of T welded carbon steel pipe

T welded carbon steel pipes containing nickel (Ni) exhibit strong corrosion resistance in acidic environments, such as those containing sulfuric acid or hydrochloric acid. The higher the nickel content in the T welded carbon steel pipe, the stronger its corrosion resistance. In general environments, adding chromium (Cr) to T welded steel pipes prevents erosion.

2024-06-11

-

Magnetic of carbon steel pipe

Carbon steel pipes are typically magnetic due to the presence of iron and their ferritic structure. The magnetic properties of carbon steel depend on its composition and the amount of ferrite present. Here are some key points regarding the magnetism of carbon steel pipes.

2024-06-11

-

API 5L X60 carbon steel pipe

This article will briefly introduce API 5L X60 carbon steel pipe.

2024-06-11

-

Introduction to seamless boiler tube welding standards

With the extensive use of boiler tubes in industrial production, the requirements for their welding quality are increasingly stringent. To ensure high welding quality, a series of national and international standards have been established.

2024-06-11

-

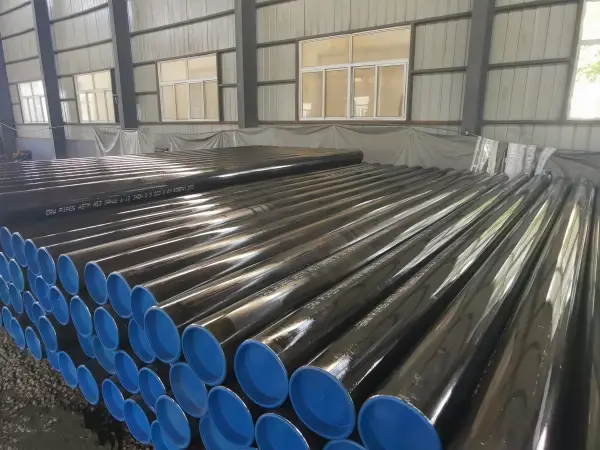

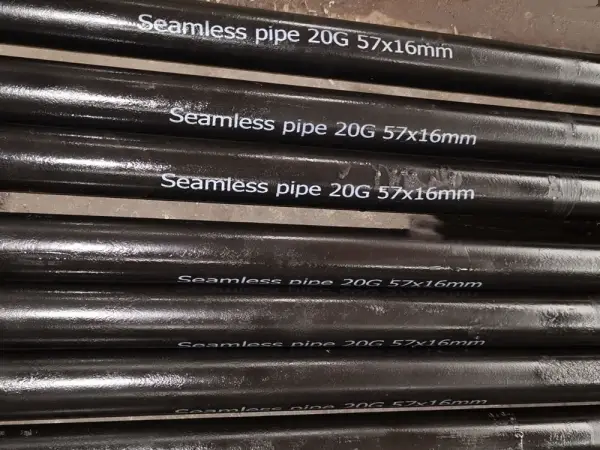

20G seamless steel pipe production process

20G seamless steel pipe is a widely used material in industries such as petroleum, chemicals, electric power, and aviation due to its high strength, high-temperature resistance, and corrosion resistance. This makes it a critical component in many industrial applications.

2024-06-07

-

Boiler tube selection and welding

Boiler tubes are essential components within a boiler, responsible for heating water to generate steam. There are two main types of tube boilers: water tube boilers and fire tube boilers. Depending on the production method, boiler tubes can be classified into seamless boiler tubes and welded boiler tubes. This article will discuss how to choose boiler tubes and important considerations for welding them.

2024-06-07

-

Strength calculation of seamless steel pipe

Seamless steel pipes are essential for transporting fluids, known for their high strength and corrosion resistance. They are widely used in industries such as petroleum, chemicals, and aviation. To ensure their safe and reliable use, strength calculations must be performed to determine their capacity to withstand external pressure and stress under working conditions.

2024-06-07